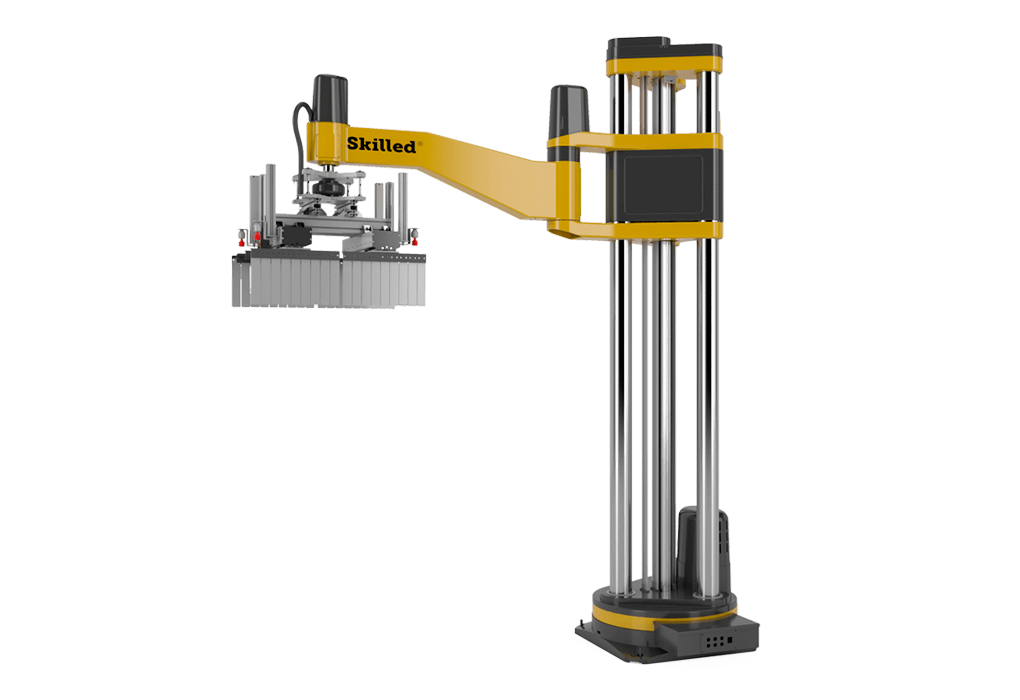

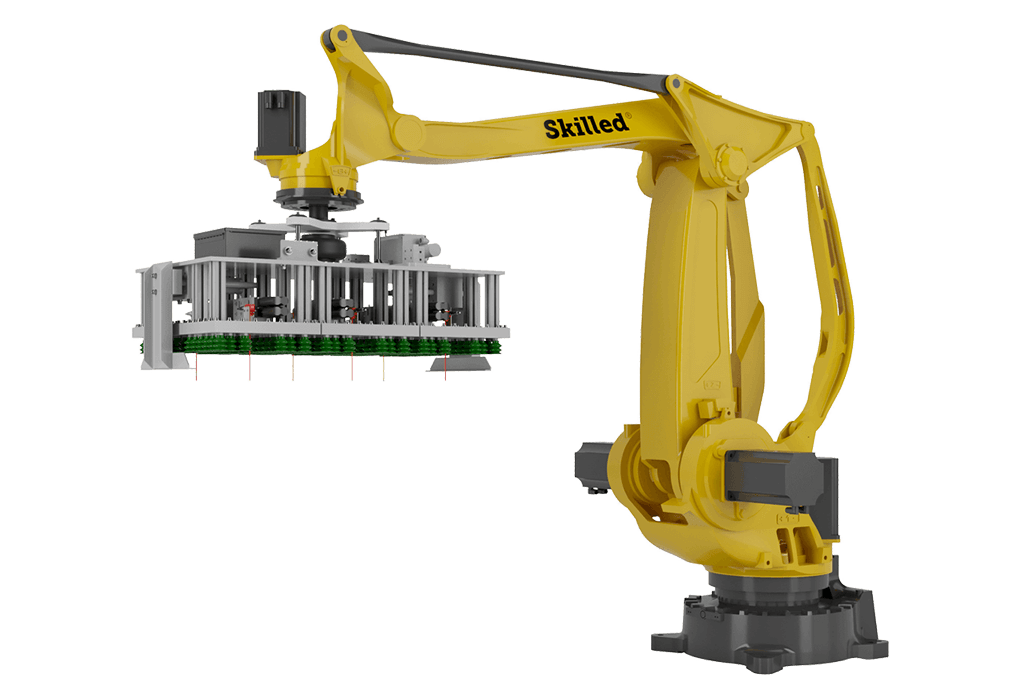

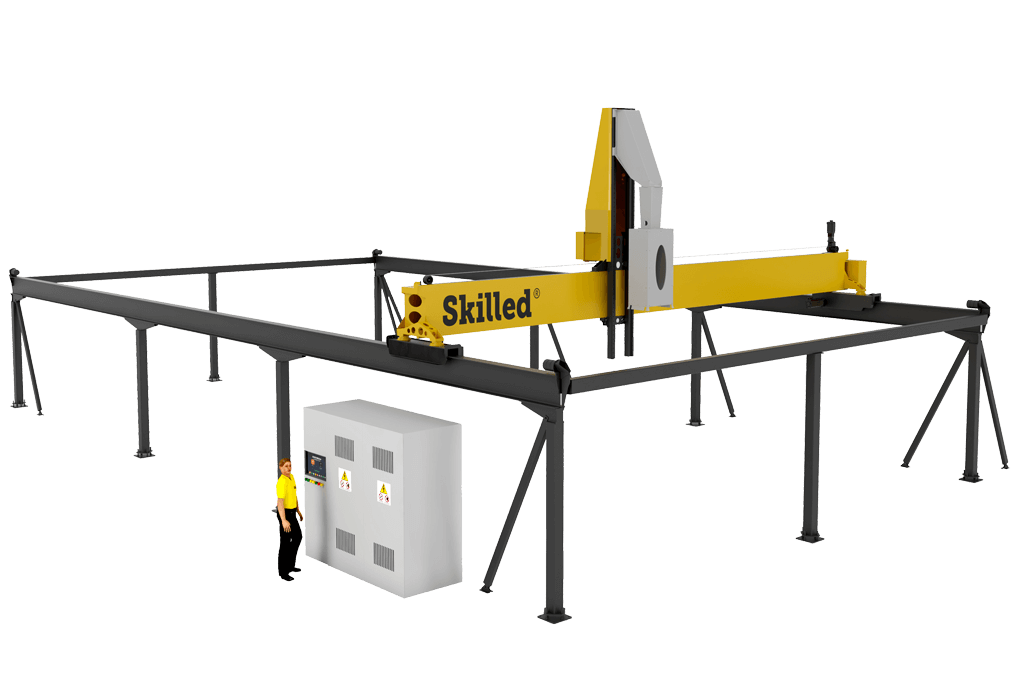

Robot palletizers

The automatic palletizing process consists of all those activities necessary to stack many different types of products on a pallet or on a slip-sheet (unitizing) in an automatic and optimized way. Skilled robots have been designed to handle this task and are well known in the Industry to be extremely efficient and reliable. The perfect design makes them compact, safe and user friendly. Skilled Group offers different robot families complete with a reliable software for any palletizing challenge.